包装容器密封完整性检测参考文献

Selection of Containers/Closures for Use in Lyophilization Applications: Possibilities and Limitations

来源:

|

作者:pmo90dc87

|

发布时间 :2018-08-16

|

1979 次浏览:

|

分享到:

Abstract

The unit operation of freeze-drying is commonly employed in the pharmaceutical industry to enhance the storage stability of relatively fragile biopharmaceuticals. Yet without a suitable container closure system, the advantages of freeze-drying a biopharmaceutical product cannot be fully realized and appreciated. Primary packaging provides the first line of defense for all pharmaceutical products by maintaining the critical quality attributes (CQAs) throughout the product shelf life. Although primary packaging components are intended to provide a stable environment for the pharmaceutical products, without proper understanding they can affect the product adversely by adsorption, absorption, leaching and permeation. For biologic products, proper selection of container and closure (c/c) components is even more important as they are more sensitive compared to other small molecule pharmaceuticals. Additionally, c/c also impacts the lyophilization process development and ultimately the drug product characteristics. The composition and processing history of the packaging components can play significant role as the impurities and residuals can induce destabilization and alter the drug product characteristics. It is critical, therefore, to understand and address all of these concerns related to c/c selection for successfully developing a stable biologic product to avoid potential product incompatibilities.

The unit operation of freeze-drying is commonly employed in the pharmaceutical industry to enhance the storage stability of relatively fragile biopharmaceuticals. Yet without a suitable container closure system, the advantages of freeze-drying a biopharmaceutical product cannot be fully realized and appreciated. Primary packaging provides the first line of defense for all pharmaceutical products by maintaining the critical quality attributes (CQAs) throughout the product shelf life. Although primary packaging components are intended to provide a stable environment for the pharmaceutical products, without proper understanding they can affect the product adversely by adsorption, absorption, leaching and permeation. For biologic products, proper selection of container and closure (c/c) components is even more important as they are more sensitive compared to other small molecule pharmaceuticals. Additionally, c/c also impacts the lyophilization process development and ultimately the drug product characteristics. The composition and processing history of the packaging components can play significant role as the impurities and residuals can induce destabilization and alter the drug product characteristics. It is critical, therefore, to understand and address all of these concerns related to c/c selection for successfully developing a stable biologic product to avoid potential product incompatibilities.

微信公众号

服务热线:

联系我们

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

电话:021-56633066/56633166

手机:18500186197

邮箱:jackge@dchtest.com

网址:https://www.dchtest.com/

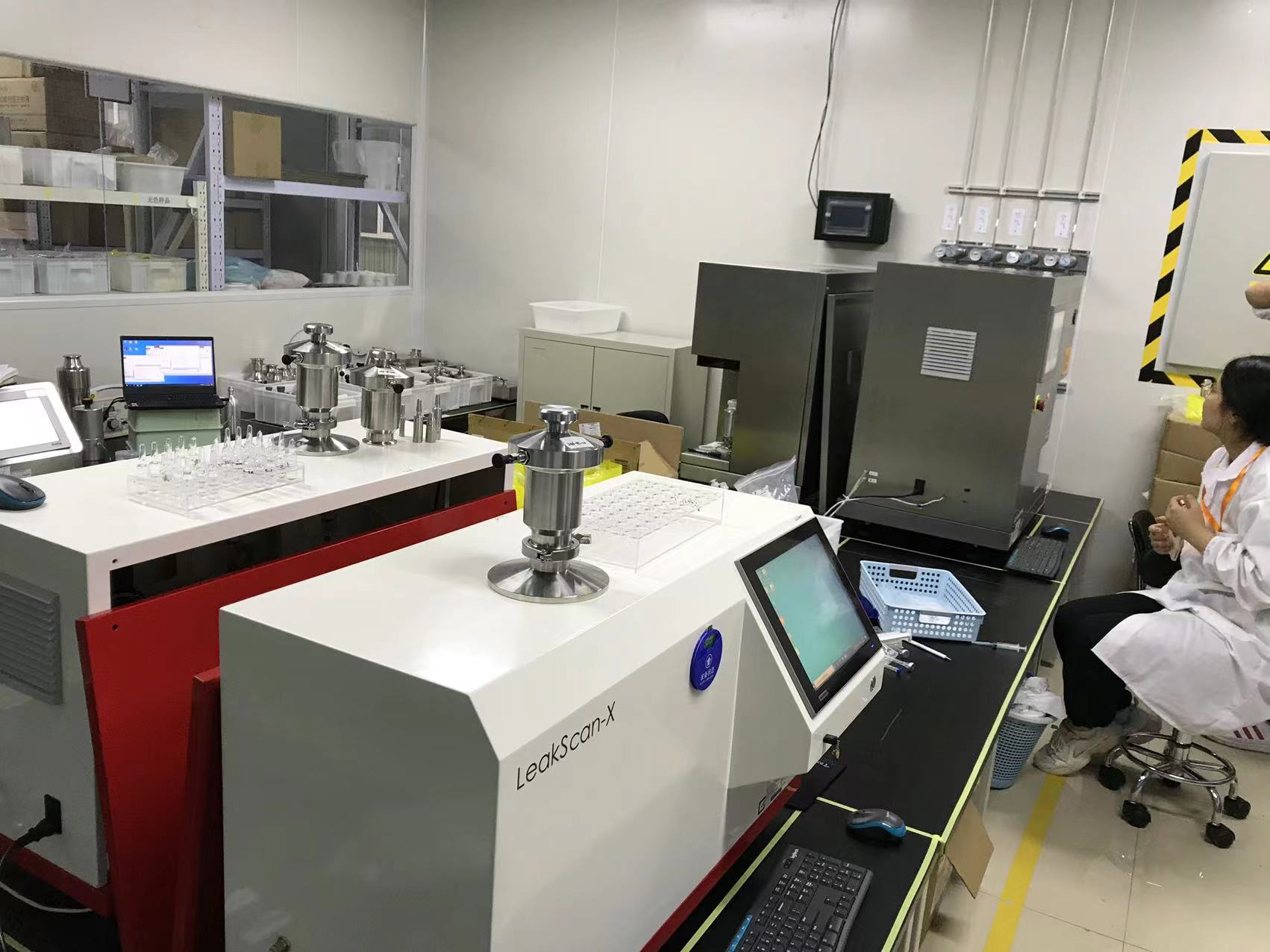

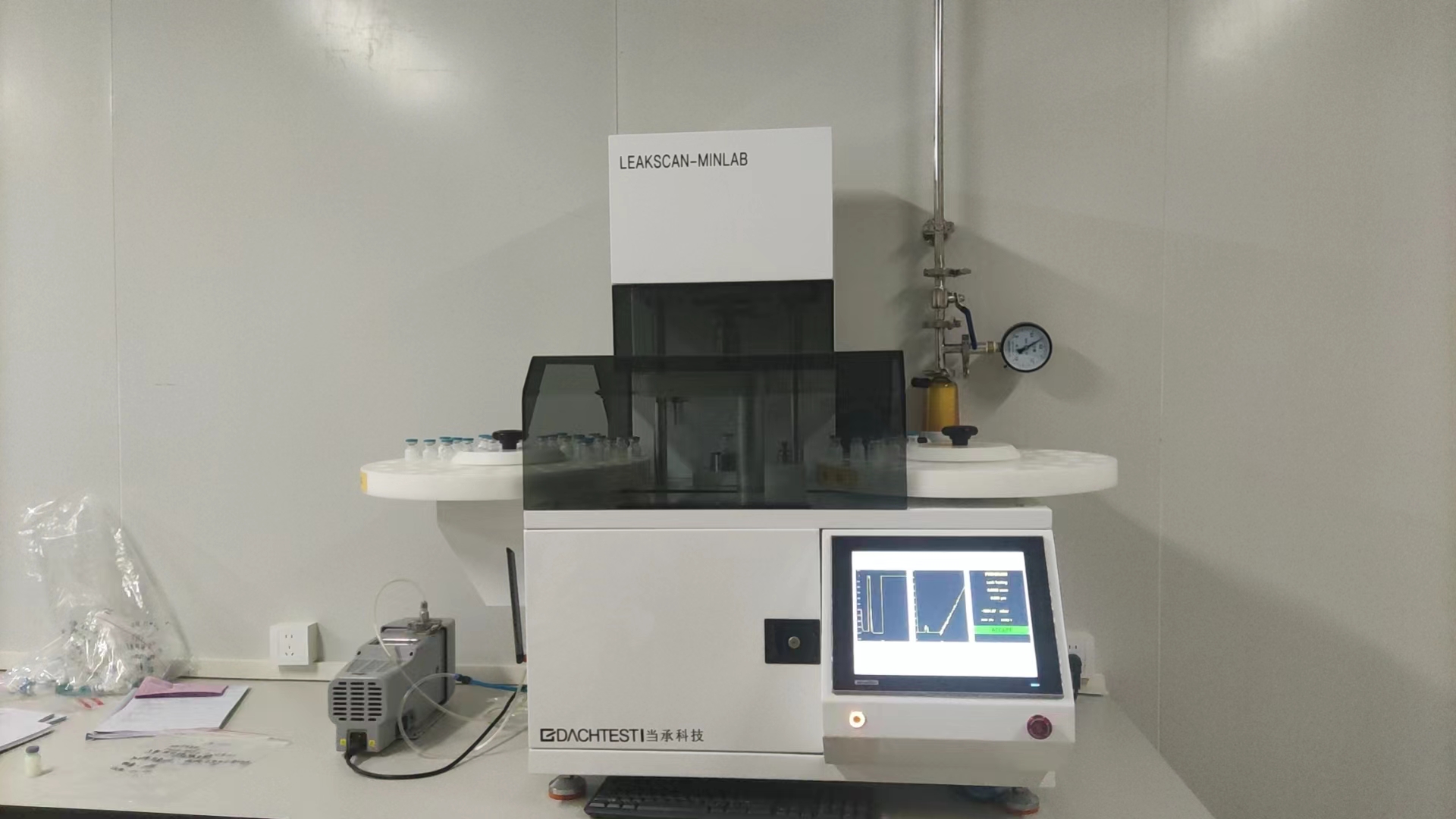

设备展示

021-56633066

产品中心

当承科技