包装容器密封完整性检测参考文献

Non-destructive testing of foil pouches. Determining a reliable method for checking for punctures

来源:

|

作者:pmo90dc87

|

发布时间 :2018-08-15

|

2611 次浏览:

|

分享到:

ABSTRACT

Several technologies used for checking for punctures in foil pouches were reviewed.

There were two that would be applicable, these were the Vacuum decay and Force decay

methods. Vacuum decay is a method where the pouch is placed into a sealed chamber and

a vacuum is applied. This vacuum will create a pressure differential from the inside of the

pouch to the outside. After the vacuum is switched off the vacuum level is monitored and

a change is measured. If a puncture exists there will be a change that is larger than one

expected due to imperfections in the test chamber. This method will work unless the

pouch has a very large puncture or it is not sealed. In this case there will not be a change

in the vacuum decay measurement.

The force decay starts like the vacuum decay except that a transducer is used to measure

the force exerted on a plate resting on the pouch. The inflation of the pouch due to

pressure differential is the source of the force. The vacuum is applied until a

predetermined force measurement is achieved then it is monitored for the rate of decay in

the force reading. The accept/reject set point determines if the pouch is good or bad.

We tried to locate off the shelf test units capable of predicting a 50µm hole 100% of the

time. Pouches were provided to various manufactures and they were asked to create

specific holes and do the required testing. It was determined that the Force Decay method

is the most appropriate test.

Several technologies used for checking for punctures in foil pouches were reviewed.

There were two that would be applicable, these were the Vacuum decay and Force decay

methods. Vacuum decay is a method where the pouch is placed into a sealed chamber and

a vacuum is applied. This vacuum will create a pressure differential from the inside of the

pouch to the outside. After the vacuum is switched off the vacuum level is monitored and

a change is measured. If a puncture exists there will be a change that is larger than one

expected due to imperfections in the test chamber. This method will work unless the

pouch has a very large puncture or it is not sealed. In this case there will not be a change

in the vacuum decay measurement.

The force decay starts like the vacuum decay except that a transducer is used to measure

the force exerted on a plate resting on the pouch. The inflation of the pouch due to

pressure differential is the source of the force. The vacuum is applied until a

predetermined force measurement is achieved then it is monitored for the rate of decay in

the force reading. The accept/reject set point determines if the pouch is good or bad.

We tried to locate off the shelf test units capable of predicting a 50µm hole 100% of the

time. Pouches were provided to various manufactures and they were asked to create

specific holes and do the required testing. It was determined that the Force Decay method

is the most appropriate test.

微信公众号

服务热线:

联系我们

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

电话:021-56633066/56633166

手机:18500186197

邮箱:jackge@dchtest.com

网址:https://www.dchtest.com/

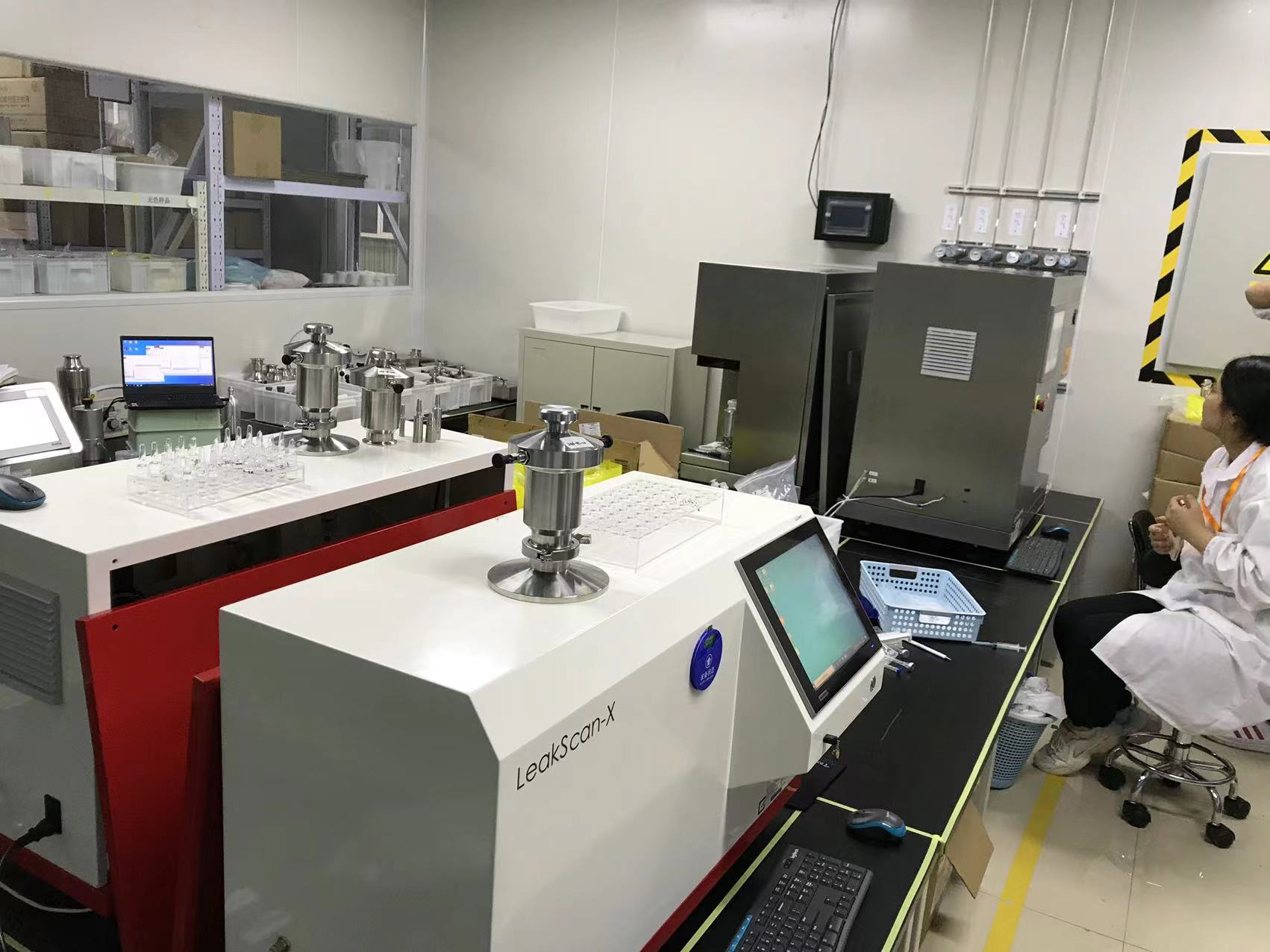

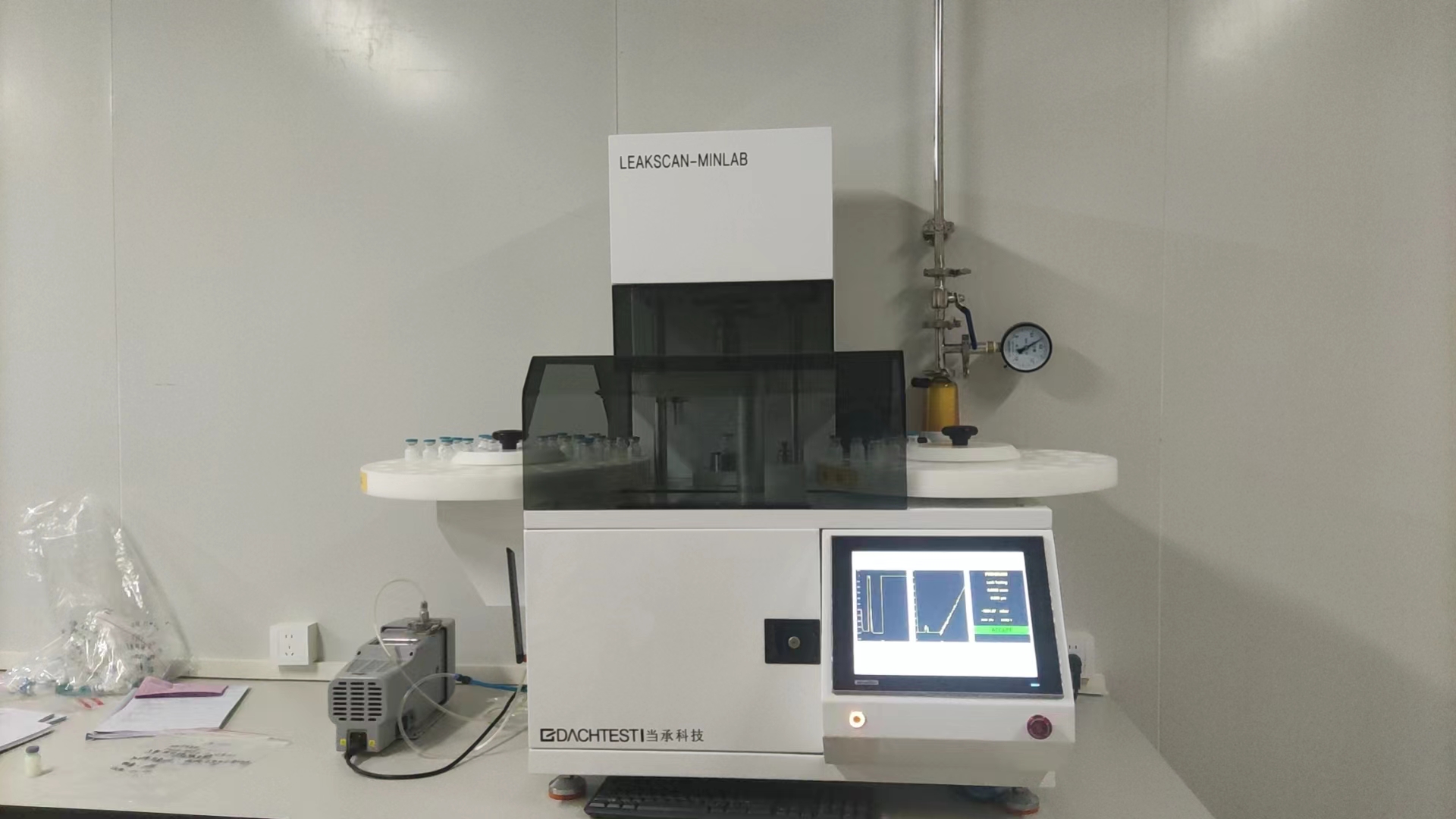

设备展示

021-56633066

产品中心

当承科技