-

11 2024-12

Impact of Container Closure on Drug Safety

Impact of Container Closure on Drug Safety

The following activities are expected to be conducted during the

development and validation phases:

1. Selection of container closure (CC) suitable to the product

2. Selection of the container closure integrity test method, including limit of

detection:

a. CCIT test method suitable for the type of container closure

b. CCIT limit of detection able to detect “leaks of concern” (those that may

result in impact to product quality and safety)

c. Validation of the CCIT, including selection of breached positive controls,

parameters, etc.

3. Demonstration of CCI after worst‐case process conditions:

a. Worst‐case vial crimping

b. Worst‐case sterilization cycles

4. Demonstration of CCI after secondary assembly (PFS into autoinjectors, assembly

of plunger rod, finger flange, safety device, etc.)

5. Demonstration of CCI after shipping -

11 2024-12

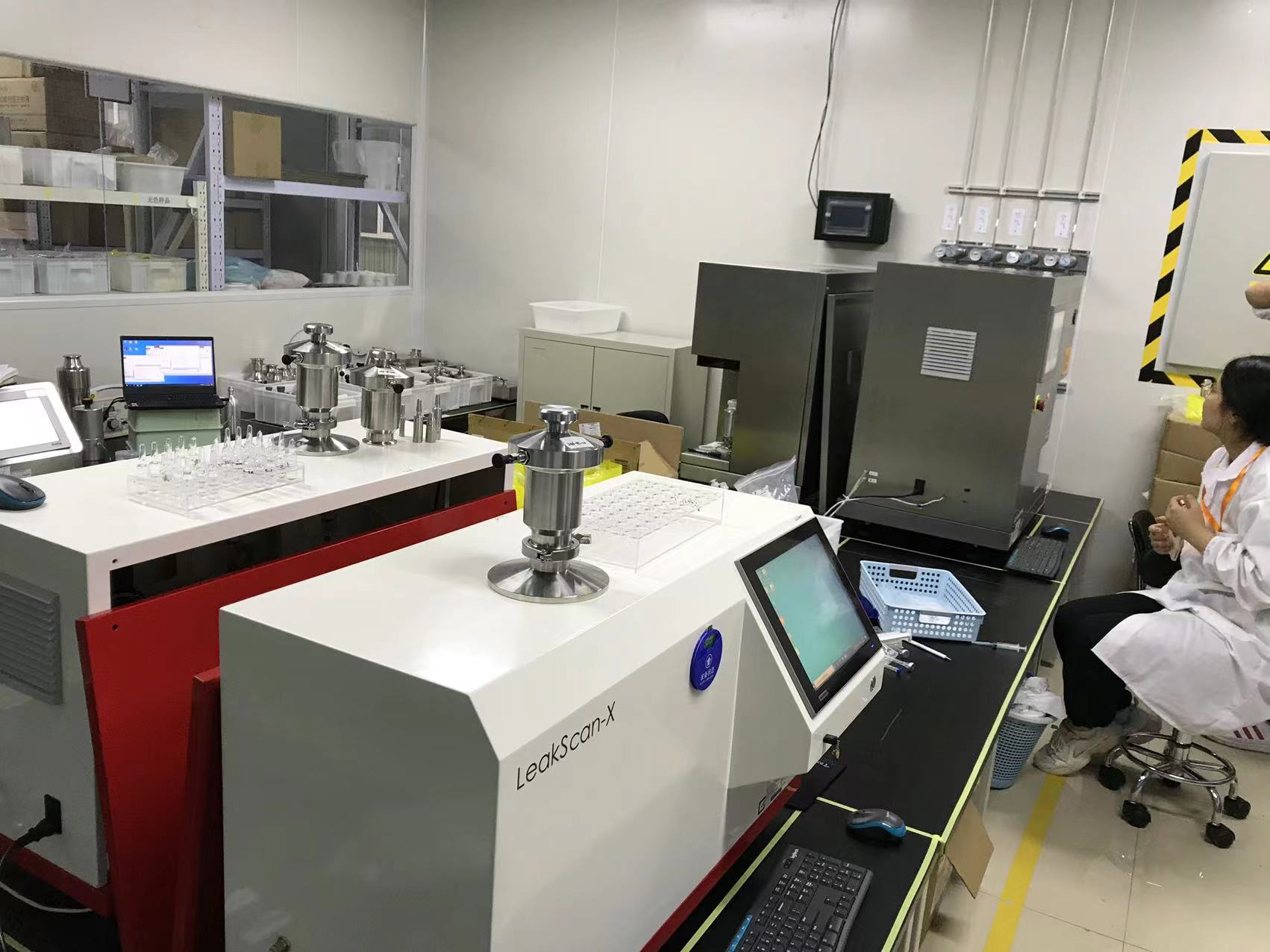

Non‐Destructive Container Closure Integrity Testing

Non‐Destructive Container Closure Integrity Testing

Prefilled Syringe

• 1 mL Glass Syringe, Staked Needle

• Holes laser drilled in barrel wall

– Air flow through defect correlated to standard orifices

– Grouped as either 5, 10 or 15 μm (± 2 μm) -

11 2024-12

Experience with Artificial Leaks and Dye Ingress Container Closure Integrity Testing (CCIT)

Experience with Artificial Leaks and Dye Ingress Container Closure Integrity Testing (CCIT)

•Void, gap, crack, hole, porosity or breach in a container closure system allowing the passage of microorganisms

•Main factor that affects critical leak size is whether or not the micro-leak is filled with liquid: microorganisms penetrate a liquid filled defect by motility or pressure differentials

•Still a lot of controversy discussions about the leak size at which the sterility may be jeopardized

–10 μm for fused silica capillary (Burrel, 2000)

–50 μm for channel leaks (Yam, K. 1995)

–0.4 μm Glass Micro-Pipettes (Kirsch, 1997)

–4 μm pinhole in steel plate (Morrical, 2007)

–20 μm OD Wire (Morrical, 2007) -

11 2024-12

Integrity performance assessment of a closed system transfer device syringe adaptor lock as a terminal closure for Luer-Lock syringes

To investigate the container closure integrity of a closed system transfer device syringe adaptor lock in combination with disposable Luer-Lock syringes as the terminal closure device. The UK National Health Service (NHS) Pharmaceutical Quality Assurance Committee (PQAC) requires syringe integrity data for final storage devices of aseptic products such as chemotherapy drugs when prepared in advance and stored before use, as is standard practice for dose banded drugs. The assessment comprised both physical and microbial integrity testing of the combination close system/Luer-Lock syringe containers at syringe sizes of 1 mL, 20 mL, and 50 mL. -

11 2024-12

A case study for seal quality and container closure integrity testing across the life cycle of sterile products

•USP is a major update and a gap assessment is recommended between it and the current way of working

•A case study was presented for the following:

Building a strategy for closing gaps and mitigating risks

Rationalizing CCIT and seal quality methods as part of the quality assurance with a scientific- and risk-based approach

Applying various test methods across the product life cycle for specific CCS formats

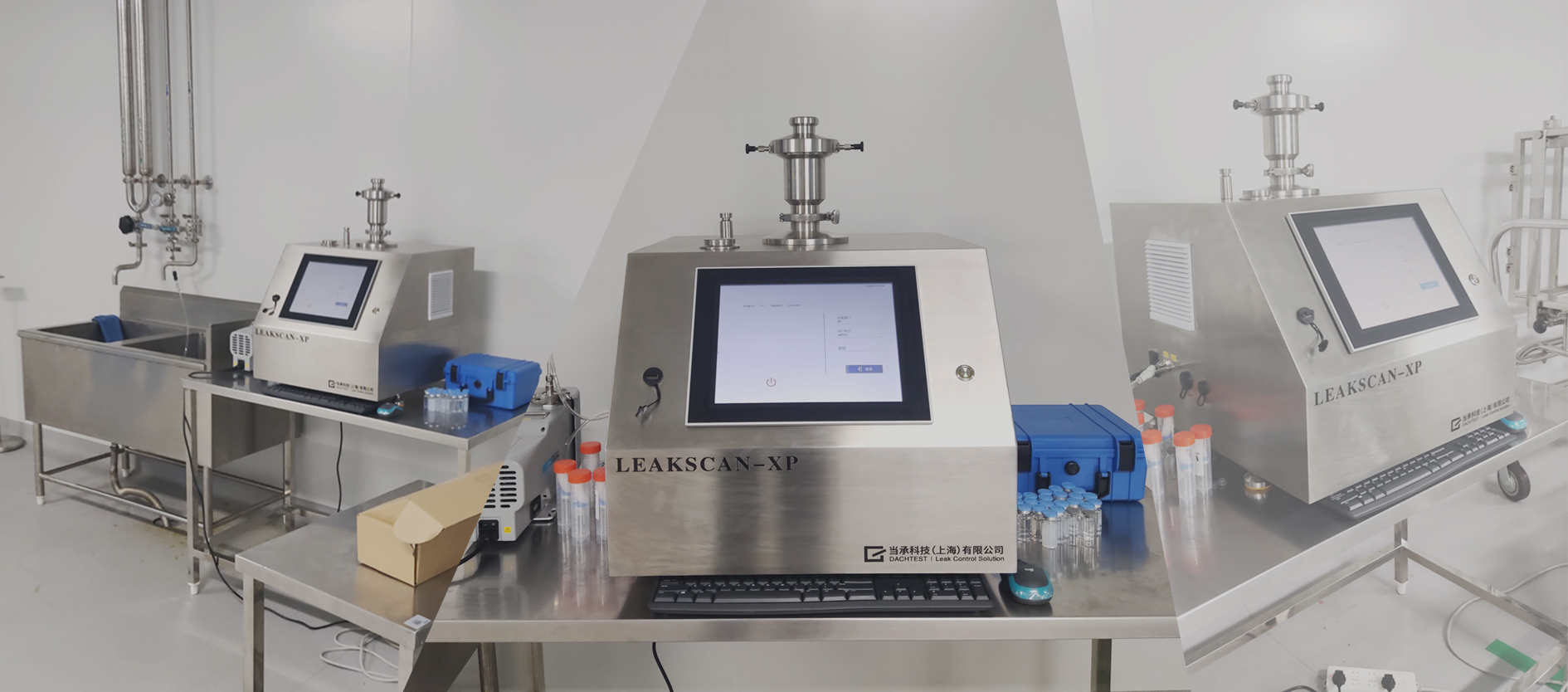

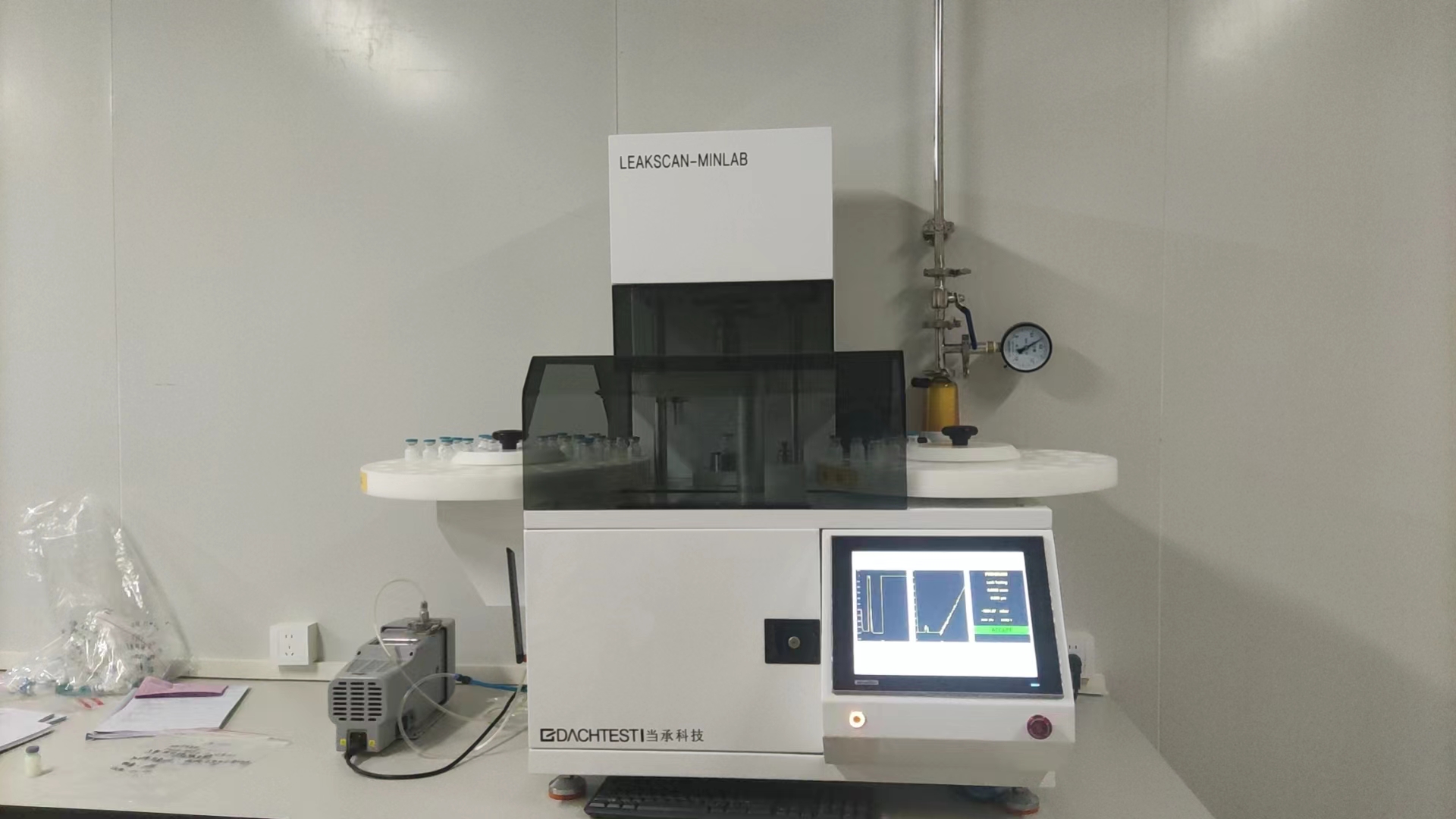

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

当承科技